Axicon 12800 barcode verifier

Direct part mark

Applications

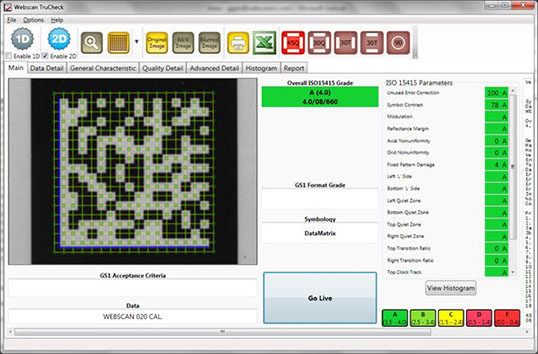

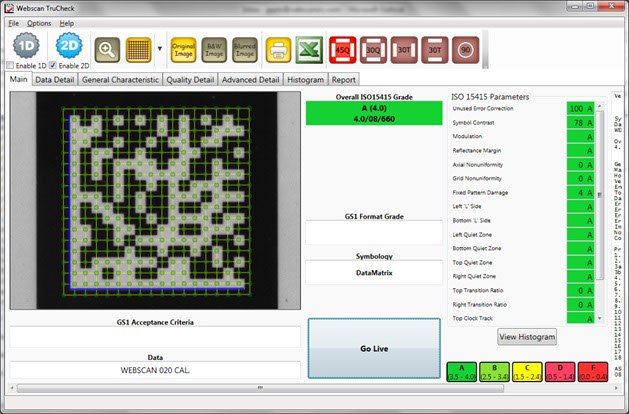

The Axicon 12800 has been specially designed to verify direct-part-marked barcodes, including Data Matrix, GS1 DataMatrix, QR Code, and GS1 QR Code two-dimensional symbols, whether laser-etched or dot peen. The smallest x-dimension is 0.150 mm or 6 mil. It has nine different lighting options to enable verification in accordance with ISO/IEC 15415 and the AIM Quality Guideline (ISO/IEC TR 29158). The Axicon 12800 allows for the angle of illumination to be set at 30º, 45º, or 90º, as required by the particular application. For 30º illumination, you can choose from four or two sides to minimise the effect of specular reflection. The field of view is 34 mm x 25.5 mm, and the verifier may also be used to verify linear barcodes in accordance with ISO/IEC 15416, provided they are no wider than 34 mm.

Features & Benefits

Fully compliant with ISO/IEC 15426-1 and 15426-2, the verifier conformance standards, and ISO/IEC 15415 and 15416, the barcode print quality specifications. It also provides the data files needed to meet the requirements of the USA CFR 21 part 11 regulations.

Hardware

CCD sensor-based 2D barcode verifier. Aperture selectable to suit application standard. Wavelength of light 660 nm.

Axicon 12900 barcode verifier

Direct part mark (flex height)

The Axicon 12900 has been specially designed to verify direct-part-marked barcodes that are difficult to read with other DPM verifiers. The verifier can be raised up to 150 mm above its base so that slightly recessed symbols, and those marked on components can be read more easily.

The verifier is moved vertically by using the manual hand wheel, and the software uses a laser-based distance measuring system to ensure that the image is correctly focused. It can read DataMatrix, GS1 DataMatrix, QR Code, and GS1 QR Code two-dimensional symbols, down to an x-dimension size of 0.152 mm. It has 5 different lighting options to enable verification in accordance with ISO/IEC 15415 and the AIM DPM Quality Guideline (ISO/IEC TR 29158): the angle of illumination can be set at 30º, 45º, or 90º, as required by the particular application.

The field of view is 34 mm x 25.5 mm, and the verifier may also be used to verify linear barcodes in accordance with ISO/IEC 15426-1, provided they are no wider than 34 mm (including quiet zones).

Axicon 12900 Flex height verifier

Direct part marking and verification

Direct part marking, in the barcoding world, means a quite different approach to the production, verification and reading of these symbols. Almost all other barcodes are printed onto a substrate, using a conventional printing press or by using on-demand printers so that the barcodes can include variable information. With these traditional barcodes the user can choose the colour of the bars to be printed, and choose the colour of the substrate – the background – so that the bars will appear dark against a pale background.

Direct park marking is different, as there is no conventional printing. There is no colour to be used, as direct part marked symbols are created on the item in a different way. (Direct part marking is the industry shorthand for the marking of very small items and components with a unique identification code so that these items can be tracked for any asset management purpose. Examples include small medical devices, surgical instruments, components (of vehicles, computers, machinery, etc), which are usually metallic, and the marking must not affect their use.)

There are two commonly used techniques for direct part marking. The first is dot peening which is the indenting of the surface with small circular marks. The indenting is carried out by a carbide or diamond tip that is struck electromechanically onto the surface of the part to be marked. The combination of these dots can create digits, text or 2D barcodes such as Data Matrix, QR Code, GS1 DataMatrix or GS1 QR Code. The use of this tip means that the dots remain separate so the image is not quite the same as a normal barcode. The dots are dulling the surface of the material so the barcode will be dull (broken up) bars against a shiny background, so both reading and verifying these images is a little more complicated.

The second technique is laser etching, which uses a focussed laser beam to mark metal or plastic parts regardless of their hardness or surface texture. The energy delivered by the laser changes the surface of the material under the focal point which will have a very small diameter, for example 30 microns. The surface may be marked as a consequence of chemical or molecular alteration, for example charring or oxidisation, to produce a change in colour. The laser can be controlled more precisely than a dot peen device so that the image does not appear to be formed from individual elements. Again this colour change will often produce dark or dull images against a more polished or brighter background, but pale images on a dark background are not that uncommon.

Conventional barcode readers, including imagers that can read two-dimensional symbols, and conventional barcode verifiers (that are intended to match the way in which barcode scanners work) will struggle to read most direct part marked symbols. There is insufficient contrast between the bars or square modules and the background to the symbol.

This has meant that both the reading devices and the verifiers have evolved to shine light onto these images at flatter angles so that the contrast between the marks and their background is increased, making the reading process more straightforward. As a consequence the verifiers used to check the quality of these images use a technique that allows for the best lighting option to be used, whether this is light being shone at 30⁰, 45⁰ or 90⁰ to the surface, and from all four sides or just two. This is not the same technique standardised by ISO/IEC 15415 Bar code symbol print quality test specification – Two-dimensional symbols. A new approach, developed by AIM to enable consistency in the quality measurement of these symbols, has been adopted by ISO/IEC as a Technical Report, and it is called ISO/IEC TR 29158 – Direct Part Mark (DPM) Quality Guideline.

So verifiers that are to be used to measure the quality of direct part marked symbols need to comply with both ISO/IEC 15415 and ISO/IEC TR 29158 to give users the ability to gain consistent results.

Axicon’s range of 2D barcode verifiers includes one that is specially designed for DPM symbols. The Axicon 12800 has a field of view of 34 mm x 25.5 mm, and can also be used to verify linear barcodes in accordance with ISO/IEC 15416, provided they are no wider than 34 mm. The x-dimension of the 2D symbol can be as small as 0.127 mm or 6 mil, and it has nine different lighting options to enable verification in accordance with either ISO/IEC 15415 or ISO/IEC TR 29158.